When you think about the future of sensing, you might picture thinner, faster, smarter devices.

But for Joseph Stephens, COO/CFO of NanoSen, the real revolution starts somewhere else entirely — in the material itself. At NanoSen, that revolution takes shape through flexible force sensing technology — materials that make precision measurable.

“We’ve spent years trying to make sensors survive what engineers do to them,” Stephens says with a grin.

“Now, they finally can.”

From Lab Breakthrough to Market Reality

NanoSen is built on more than a decade of research at TU Chemnitz, where the team developed a new generation of polymer nanocomposite (PNC) materials — soft, flexible, and electrically active.

Through a proprietary process, NanoSen transforms medical-grade silicone into a thin, conductive, and durable sensor material.

The result: a 0.4 mm film capable of measuring forces from 0.01 N to 150 N, surviving 6,200 N overload, and withstanding 20 million load cycles — without performance loss.

“It was the perfect moment to spin out,” says Stephens.

“The technology was ready, the demand was real, and the transition from lab to industry finally made sense.”

From Resistance to Impedance – A New Way to Sense Force

Traditional force sensors work by measuring either resistance or capacitance.

NanoSen’s materials do both — and more.

“When our PNC is compressed, the conductive nanoparticles move closer together,” Stephens explains.

“That changes resistance and capacitance at the same time. We measure both — that’s impedance — and the result is far more stable and precise.”

By combining two measurement principles, NanoSen sensors compensate for drift and temperature effects, reducing calibration effort and delivering cleaner, more reliable data.

In other words: fewer errors, more trust in every measurement.

Designed for Flexibility — and for Designers

NanoSen’s vision goes beyond selling sensors.

Instead, they deliver the material itself — so engineers can shape, cut, and integrate it into their own systems.

A single sensor element only needs two layers: the PNC film and an electrode structure.

Those electrodes can be printed on substrates like PET, TPU, or polyimide, depending on the flexibility and performance required.

“We want to make sensing as customizable as circuit design,” Stephens says.

“That’s why we provide the material — not just the product.”

The benefit? Shorter development cycles, lower costs, and the freedom to experiment.

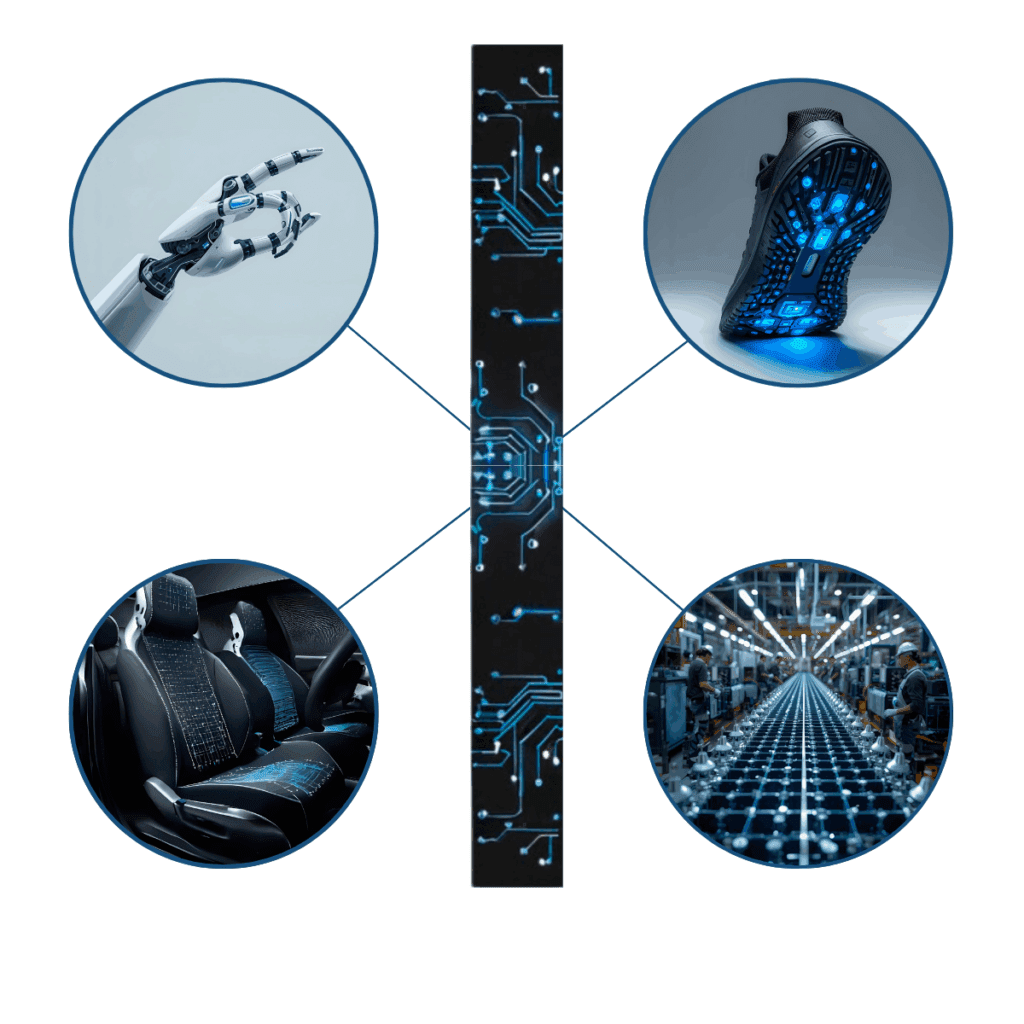

Real-World Impact: From Robots to Hospital Beds

From robotics to healthcare, NanoSen’s flexible force sensing technology enables precise, reliable measurements even in complex, dynamic environments.

- Healthcare: smart beds and cushions that detect and distribute pressure to prevent sores and support caregivers.

- Robotics: grippers that can tell whether they’re holding an egg or a motor — without breaking either.

- Industrial automation: durable sensors for predictive maintenance and process monitoring, built to last under extreme conditions.

“Our sensors perform where others fail,” says Stephens. “They don’t just measure — they endure.”

From Idea to Measurement in Minutes

For those who want to test the technology right away, NanoSen developed the PNC Force Sensor Kit — a compact plug-and-play system with five sensors and a ready-to-use readout board.

It connects via USB or I²C, includes calibration tools, and lets users run force measurements within minutes.

And for companies aiming to integrate PNC materials into products, NanoSen provides full development support — from first prototype to production-ready design, often within just a few weeks.

Scaling with Consistency

Behind the technology lies a production system designed for scale.

NanoSen’s automated line currently produces around 380 m² of material per year — enough for over 1.2 million sensors — and can quadruple output within months if demand rises.

“Scalability was part of our thinking from day one,” Stephens notes.

“You can’t call something an industrial material if it only works in the lab.”

Durability as Design Philosophy

When asked where he personally sees the biggest impact, Stephens laughs.

“I used to be a mechanic,” he says. “You know what breaks first in most tools? The buttons.”

Mechanical switches wear out, corrode, or fail over time. NanoSen’s technology could replace them — no moving parts, no wear, just a durable, touch-sensitive layer that lasts for years.

“That’s what excites me,” Stephens says. “We’re building technology that disappears into the product because it simply works.”

The Future of Force Sensing

For NanoSen, the future of sensing isn’t just about smaller chips or faster processors — it’s about materials that adapt.

By combining sensitivity, endurance, and design freedom, their flexible force sensing technology is laying the foundation for a new era of smart materials.

“Sensors shouldn’t be fragile,” Stephens concludes.

“They should evolve — just like everything else in technology.”

Learn More

Explore NanoSen’s technology and products:

nanosen.de/sensor-technology

shop.nanosen.de

No responses yet