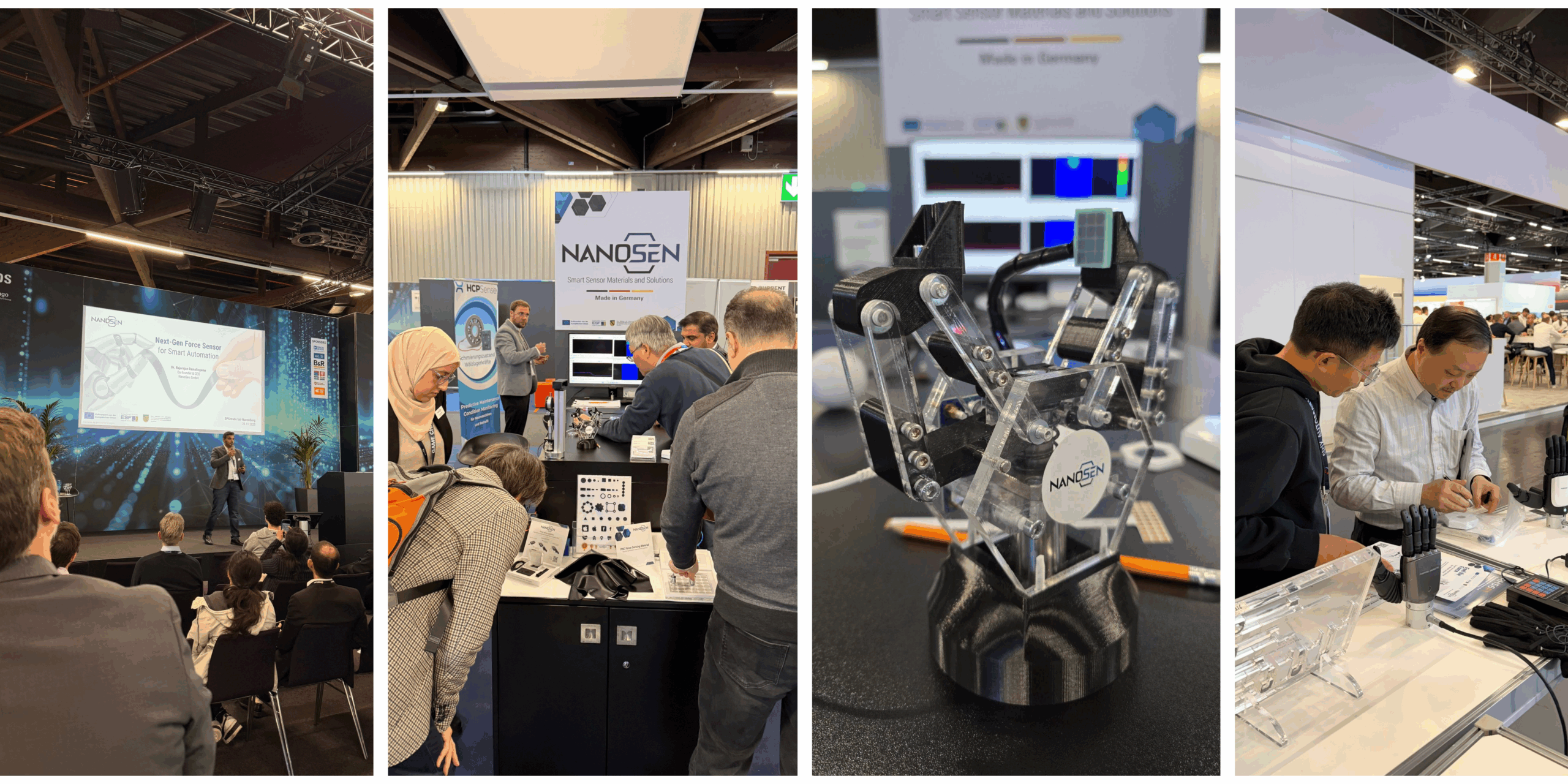

SPS was intense, exciting, and honestly a lot of fun.

Between demos, live tests, and a non-stop stream of curious engineers, we had countless conversations about our PNC technology.

But after three days, one thing became very clear: so many people asked the same five questions.

And they’re good questions — the kind that say a lot about where the industry is headed.

So here they are, along with the answers we shared at the booth.

1. “So… what does NanoSen actually do?”

We develop force sensing materials and electronics based on advanced Polymer Nanocomposites.

In simple terms:

We take a soft, medical-grade silicone, make it electrically conductive through a highly controlled nanocomposite process, and turn it into a thin material that changes its electrical properties when force is applied.

All in a format that is flexible, thin, robust, and surprisingly sensitive.

2. “What makes your material so different?”

Great question — and one we love answering.

Our PNC material is:

- ultra-thin

- highly sensitive, even at low forces

- extremely durable, surviving millions of cycles

- overload-resistant

- temperature-resistant

- stable under bending, long-term load, and mechanical stress

It simply performs in situations where classical sensors struggle — or don’t survive.

3. “How do I integrate this electronically?”

You have two options:

A) Use our ready-to-go electronics

Our Sensor Kit and our Force Matrix Kit include:

- impedance-based readout

- firmware

- USB + I2C interfaces

Most people at SPS were surprised how quickly you can get meaningful data — as in: minutes.

If you want to design your own setup:

B) Integrate it into your own electronics

- all you need is electrodes + PNC material

- you choose the geometry

- you choose the substrate

- you integrate the impedance measurement

And yes — we happily support teams that want to develop their own custom sensors.

4. “Where can this be used?”

Anywhere forces matter — especially when traditional sensors are too thick, too fragile, or too limited.

The applications visitors asked about most:

- load cells

- tactile sensing for robotics

- grip force distribution

- soft surfaces and wearables

- medtech pressure distribution

- test rigs and material analysis

5. “Where do you actually produce this?”

This was one of the most frequent questions — and one we’re proud to answer:

Right here in Chemnitz.

We formulate, manufacture, characterize, and refine the material ourselves.

No outsourcing. No mystery supply chains.

Just engineering, chemistry, and a lot of testing – in-house.

Our favorite moment from SPS

If we had to pick one highlight from all the conversations at SPS, it would be this:

After we explained somebody how the material works and what makes it different, he paused for a moment, looked up, and said:

“…that’s genuinely awesome sh*t.”

And honestly, that reaction made us laugh — it somehow captured the whole week.

Many people who touched, bent, pressed, or tested our material responded with the same kind of curiosity and excitement, which was really encouraging for us.

- “Cool tech.”

- “This is smart.”

- “I want to try this in my setup.”

In short:

the reactions were genuinely positive — and that meant a lot to us.

It didn’t matter whether someone came from robotics, automation, medtech, or just stopped by out of curiosity – seeing people understand and enjoy the technology was something we really appreciated.

And we’re excited to keep building on it.

No responses yet