For decades, force sensing has been dominated by resistance-based measurement principles. Force Sensitive Resistors (FSRs)1 are easy to integrate, cost-effective, and widely deployed across many applications.

But as force sensing moves into systems that demand higher reliability, long-term stability, and environmental robustness, the limitations of resistance-only measurement become increasingly evident.

This article examines where resistance-based force sensing reaches its natural limits – and why force sensing impedance technology represents a fundamentally more robust approach.

The Natural Limits of Measuring Resistance

The operating principle of resistance-based force sensors is simple:

apply force → measure resistance → infer load.

In stable laboratory conditions and low-demand applications, this approach can be sufficient.

In real-world systems, however, resistance measurements are inherently influenced by multiple factors that are not related to force itself.

Typical challenges include:

- Long-term signal drift

- Temperature-dependent behavior

- Mechanical hysteresis

- Material aging

To compensate, engineers rely on calibration routines, filtering, lookup tables, and periodic recalibration. While these methods can correct the signal temporarily, robustness is achieved through compensation – not by design.

Resistance delivers a single electrical value. When environmental or material conditions change, that value changes as well, often in ways that cannot be reliably separated from the actual force input.

Force Influences More Than Resistance

When mechanical load is applied to advanced sensing materials, the electrical response is not limited to a change in resistance.

In the sensing layers, force also affects:

- Contact interfaces between conductive domains

- Microstructural arrangements within the material

- Mechanical load changes the effective capacitance of the sensing structure

- Time-dependent viscoelastic material behavior influences the electrical signal under sustained load

These effects are intrinsic to the material and highly repeatable.

Resistance-based readout does not allow these effects to be observed or separated individually.

Force sensing impedance technology is designed to observe the full electrical response of the material, rather than reducing it to a single resistance value.

From Signal Compensation to Material Understanding

Force sensing impedance technology follows a fundamentally different measurement philosophy.

Instead of asking only how much current flows, it evaluates how the sensing material responds electrically under mechanical load. By analyzing the frequency-dependent impedance behavior, characteristic signatures of the material emerge.

This enables the system to distinguish force-induced changes from external influences such as temperature variations or long-term material aging.

The result is not just another force value, but a stable, interpretable, and physically meaningful signal.

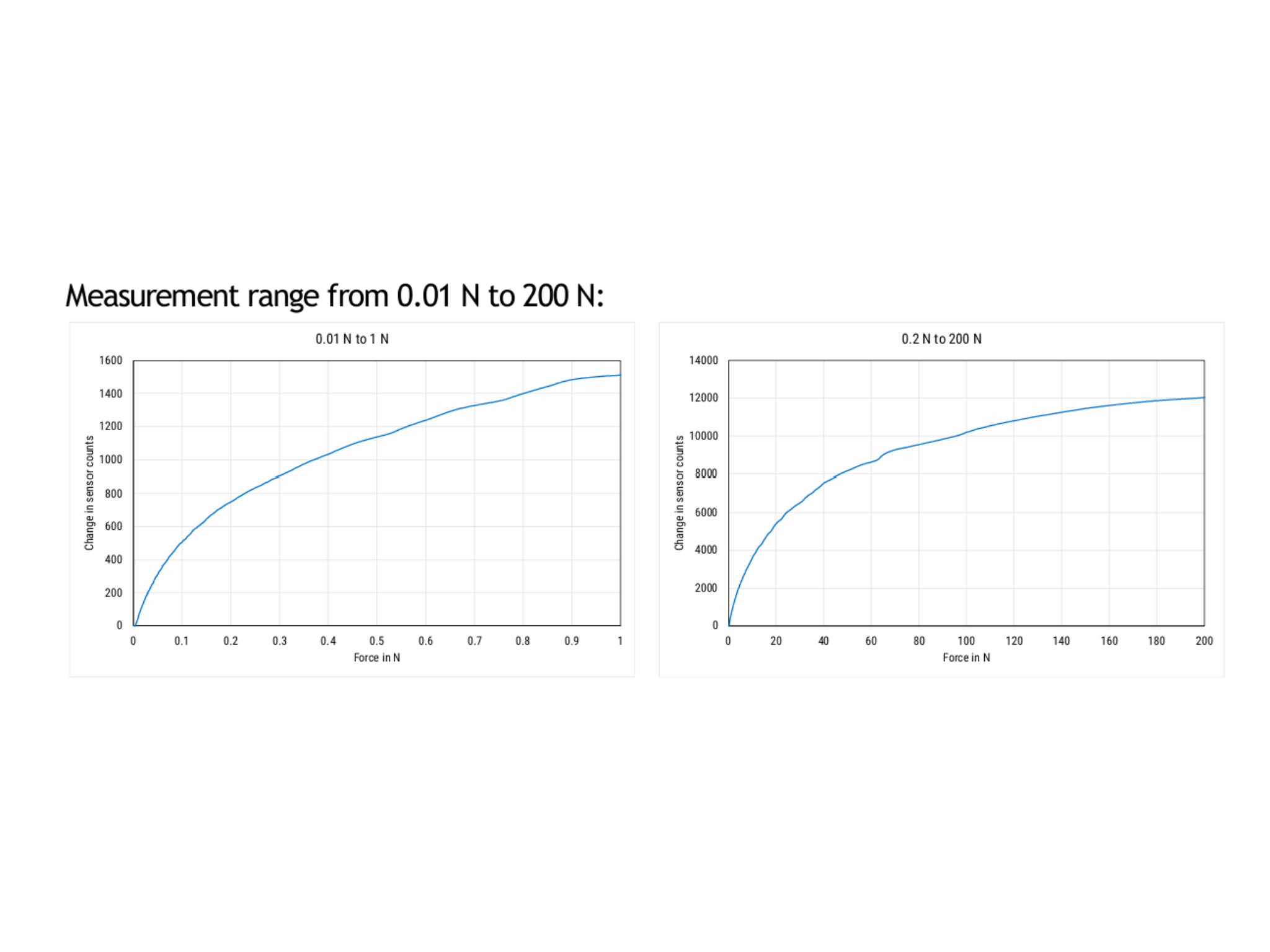

In practical applications, force sensing impedance technology enables:

- Significantly reduced drift over time

- Improved robustness across wide temperature ranges

- High repeatability throughout the sensor lifetime

- More information extracted from the same the same thin-film sensor geometry

Stability is no longer something that needs to be corrected afterward.

It becomes an inherent property of the sensing architecture.

Why This Matters Today

Force sensing is increasingly deployed in applications where uncertainty is costly or unacceptable, including:

- Robotics and human–machine interaction

- Medical, rehabilitation, and assistive devices

- Industrial automation and quality monitoring

In these environments, estimating force from a drifting or unstable signal is not sufficient. Systems require sensing principles that scale with complexity, reliability demands, and long-term operation.

Force sensing impedance technology addresses these requirements at the measurement principle level – not through post-processing.

Resistance Is Futile – Incomplete, Not Obsolete

As materials, applications, and performance expectations evolve, sensing technologies must evolve as well. Force sensing impedance technology is not a workaround or an incremental improvement.

It is a shift in perspective – from compensating signals to understanding material behavior.

Resistance has reached its limits.

Force sensing impedance technology is the way forward.

Curious how force sensing impedance technology works in practice – and how polymer nanocomposite materials enable stable, ultra-thin force sensors?

Explore our technology or contact us to discuss your application.

- “FSR” is a commonly used abbreviation for force sensitive resistors.

Trademarks are the property of their respective owners. ↩︎

No responses yet