Customizable PNC material for force sensing applications

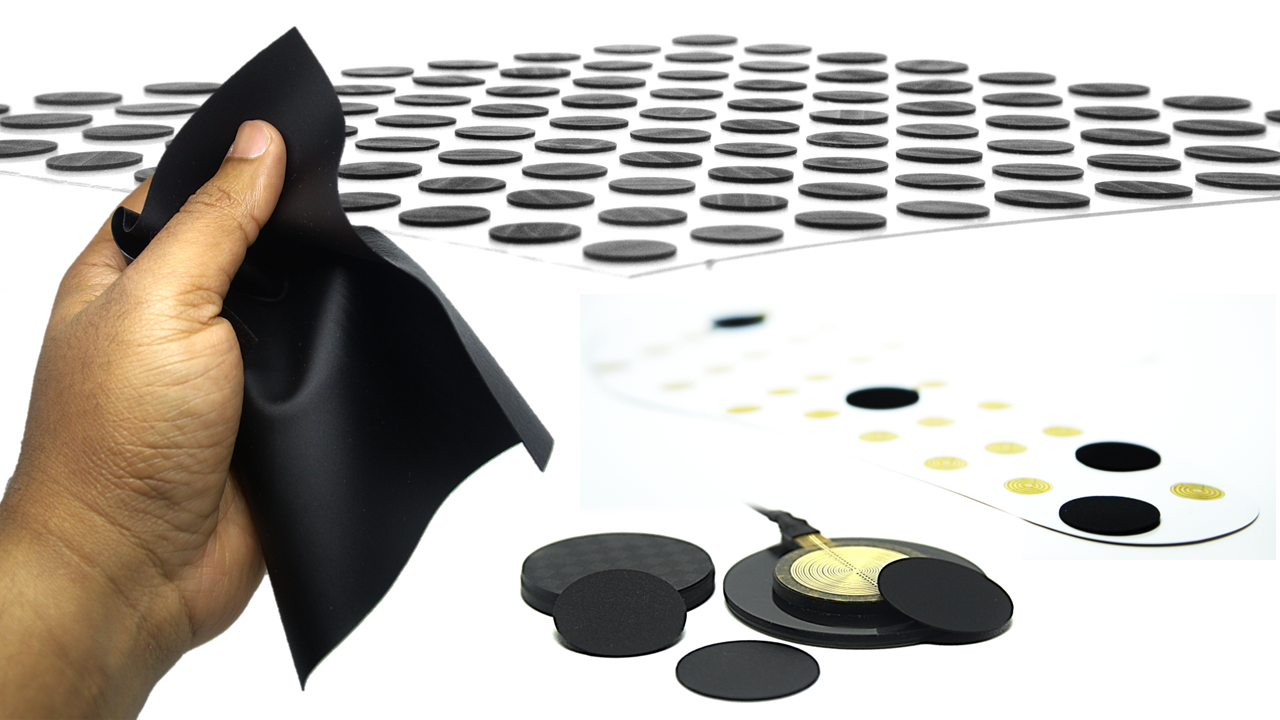

We offer our polymer nanocomposite (PNC) sensor material as an advanced force sensing material that combines polymers with functional nanomaterials.

The PNC material forms a highly sensitive and adaptable medium for force measurement and exhibits enhanced mechanical and electrical properties compared to conventional force sensing materials.

Flexibility

PNC sensor material can be processed in various shapes and sizes to meet application-specific requirements.

High sensitivity

Developed for accurate measurements even with minimal forces.

adaptability

Developed for accurate force measurements, including low-force and subtle load changes.

Durablity

Engineered for long-term use under mechanical load while maintaining performance stability.

Innovative PNC Material core

Specific advantages

The PNC material forms the core sensing element of NanoSen’s sensor systems and evaluation kits.

In combination with specially developed readout electronics, it enables stable and repeatable force measurements.

Detailed insight into the performance and characteristics of the PNC material for impedance-based force measurement applications is provided in the following documentation:

Impedance Sensor Kit Technical Data Sheet

Various readout methods

The PNC material supports impedance-based readout to convert mechanical force into an electrical signal.

Long-term stability

Under long-term mechanical load, the PNC material returns to its original shape without permanent deformation.

Compression in microns

The PNC material has a thickness of 0.4 mm and allows precise measurement of up to 85 µm of compression.

Overload resistance

For a sensor with a diameter of 20 mm, the PNC material saturates at 200 N and withstands overloads of up to 6200 N without material damage.

Absolute measurements

Compression of the PNC material changes its electrical conductivity.

Measured values remain stable in the compressed state without requiring a null reference point.

Temperature stability

The base material is a medical-grade elastomer.

The operating temperature range is from −20 °C to 230 °C, with no observed material degradation within this range.